Covering all areas of industrial automation, from software development to system and robot design.

Reliable SCADA solutions, developed for future-ready operations.

UNIFIED CONTROL SYSTEMS

Our SCADA solutions are not monolithic; they are built on reusable modules, with unified standards based on consistent tag libraries, screen templates, hierarchical alarms, and centralized parameter management. Thanks to our expertise with environments such as Ignition, Movicon WebHMI, Zenon, and Wonderware InTouch OMI, we provide complete support to OEMs who do not want to be tied to a single vendor.

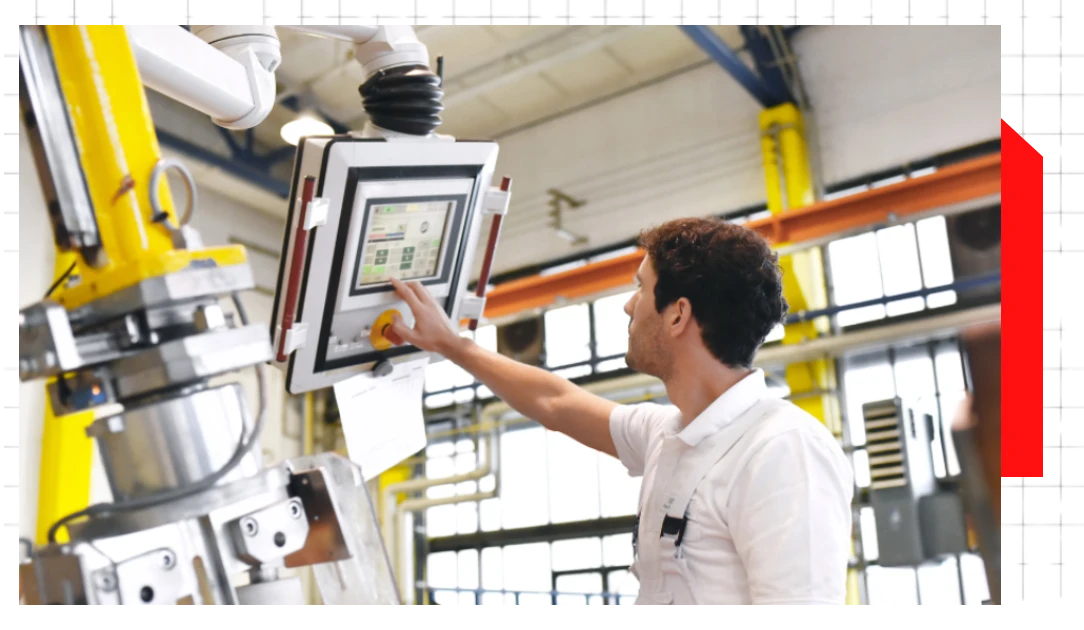

FULL PRODUCTION VISIBILITY

Production is monitored through intelligent, unified dashboards that collect real‑time data on machine status, alarms, performance, and quality. This information is accessible from any device and can be customized to provide detailed views such as alarm heat maps, line performance, energy consumption, and potential future trends.

ADVANCED SCADA & AUTOMATION

Advanced alarm management and diagnostics, integrating intelligent severity handling, interactive fault‑resolution tools, and AI‑driven predictive alerts to reduce downtime and accelerate troubleshooting.

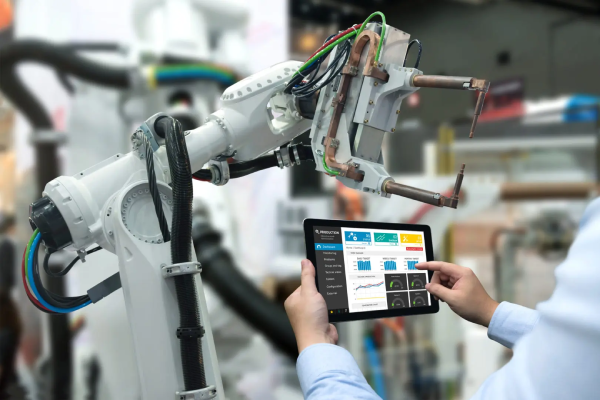

SCADA integration across PLCs, robots, IT, and cloud, enabling bidirectional MES/ERP data flows and hybrid edge-cloud architectures for sync production, multi‑site scalability, and real‑time analytics.

Comprehensive data history and reporting built on scalable time‑series storage, automated OEE analytics, and customizable exports/API integrations for long‑term performance benchmarking.

IIoT‑enabled predictive maintenance, combining normalized edge data, trend and anomaly analytics, and automated workflows to extend asset life and streamline intervention planning.

Real‑time safety‑state visualization, hardened cybersecurity compliant with IEC 62443, and rigorous code validation for zero‑downtime deployments and secure rollbacks.

End‑to‑end SCADA lifecycle management, from prototyping to controlled migrations and scalable upgrades, delivering human‑centric Industry 5.0 interfaces that guarantee production continuity.

RELIABLE RELEASES

The DevOps approach allows us to manage SCADA projects with transparency through:

a single source of truth for code, configurations, versions, and releases;

the use of Git, CI/CD, and shared test/dev/prod environments to track every activity;

gateways and fully documented release packages for each machine.

PARTNERING WITH MANUFACTURERS

We collaborate with the OEM from the earliest stages of the project to define the supervision architecture, the most suitable SCADA platform, tag‑naming standards, and system‑integration simulation. Our specialists become an extension of the client’s internal team, supporting project activities both on‑site and remotely, and providing targeted training on major SCADA environments and related best practices.

NOT JUST SCADA PROGRAMMING

Covering all areas of industrial automation, from software development to system and robot design.

2D/3D CAD modeling for components, industrial plant layouts, and custom machinery.

AI, Digital Twin, Edge‑Cloud Computing, and Cybersecurity to deliver Industry 4.0 solutions.

From needs assessment to commissioning, with smooth integration into production lines.

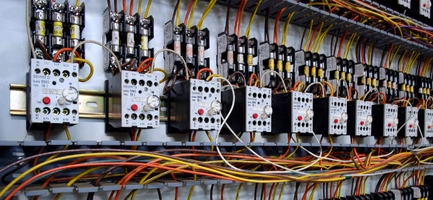

Smart PLC program development, testing, and commissioning for reliable system control.

End‑to‑end electrical panels, on‑machine wiring, and technical documentation.