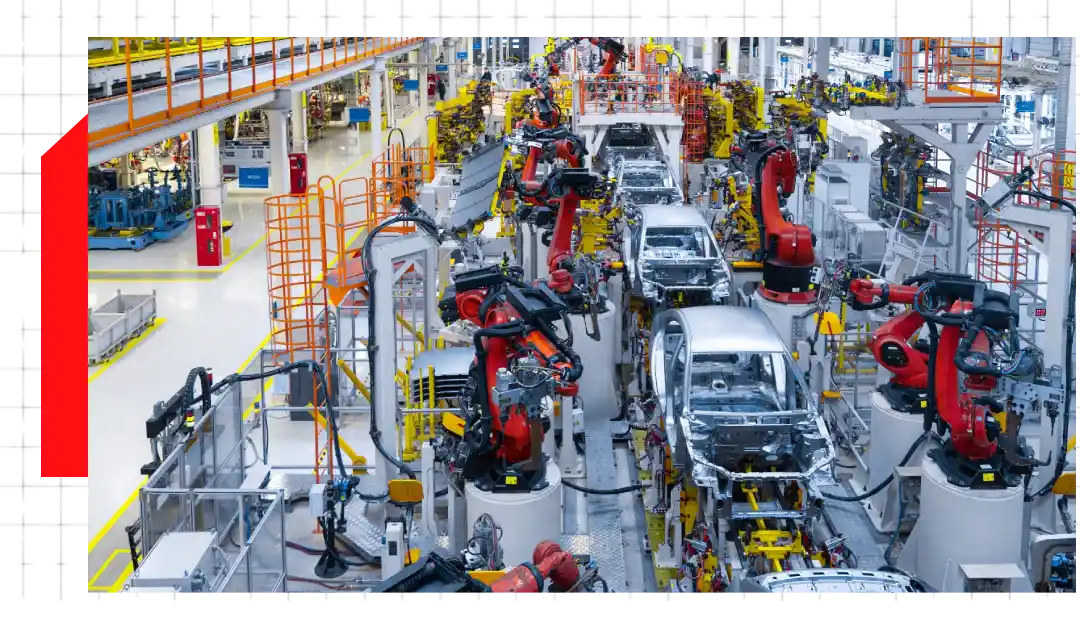

Covering all areas of industrial automation, from software development to system and robot design.

Advanced robotic solutions, tailored to every production environment.

REPLICABLE ROBOT ROUTINES

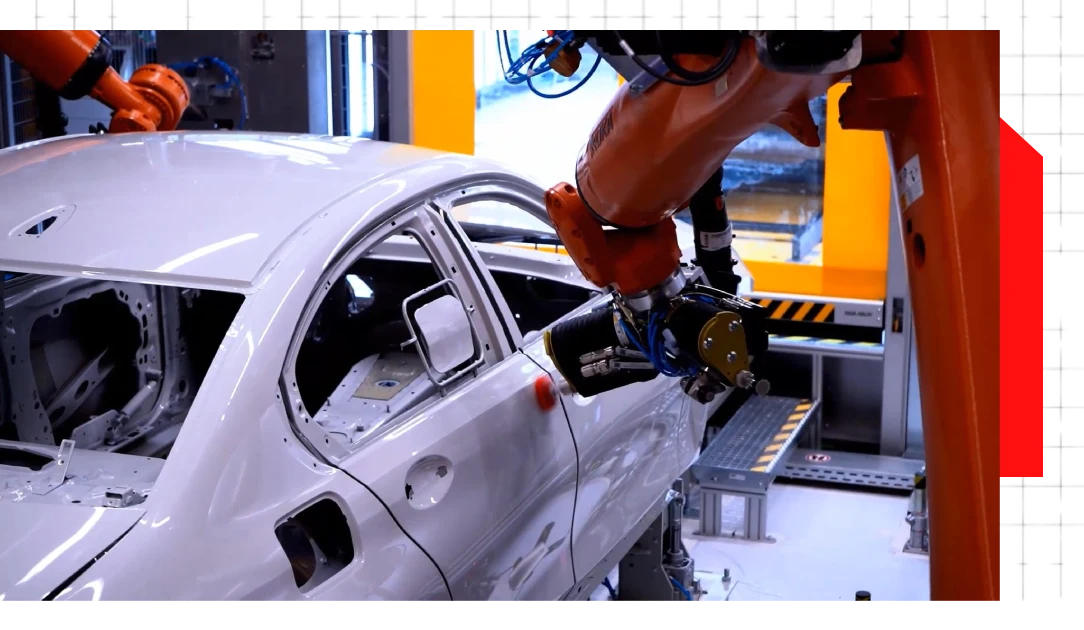

Our service is designed for machine builders who want to use a single program across multiple machines or production lines. To achieve this, we develop scalable libraries and unified standards for robotic cells dedicated to handling, palletizing, pick‑and‑place, welding, assembly, and machining. Our programs also provide multi‑brand support, with extended compatibility for ABB, Fanuc, KUKA, Universal Robots, Stäubli, and Epson.

SHARPER MOVEMENTS, FASTER CYCLES

We implement complex trajectories to enable coordination among multiple robots, allowing them to operate together with smooth movements, without sudden interruptions or collision risks thanks to integrated vision systems. With our intervention, robotic cycle times are reduced by up to 40%, and performance can be further optimized through force/torque control, path blending, predictive motion, and dynamics simulation.

ADVANCED ROBOTICS & AUTOMATION

Creation of a unified platform with reusable libraries and cell standards, which simplifies programming, reduces commissioning time by up to 50%, and ensures greater consistency between teams.

Development, testing, and validation in simulator and with Digital Twin before FAT, achieving up to 70% reduction in field startup time and optimized performance prior to the physical build.

Integration of robots, PLCs, motion controllers, and vision systems for smart cells, with HMI‑ready programming and interfaces to MES/Cloud for efficiency, traceability, and predictive maintenance.

Integration of validated safety logics and mission‑critical software quality, with robust diagnostics and code review to deliver robots compliant with ISO/TS 15066 standards.

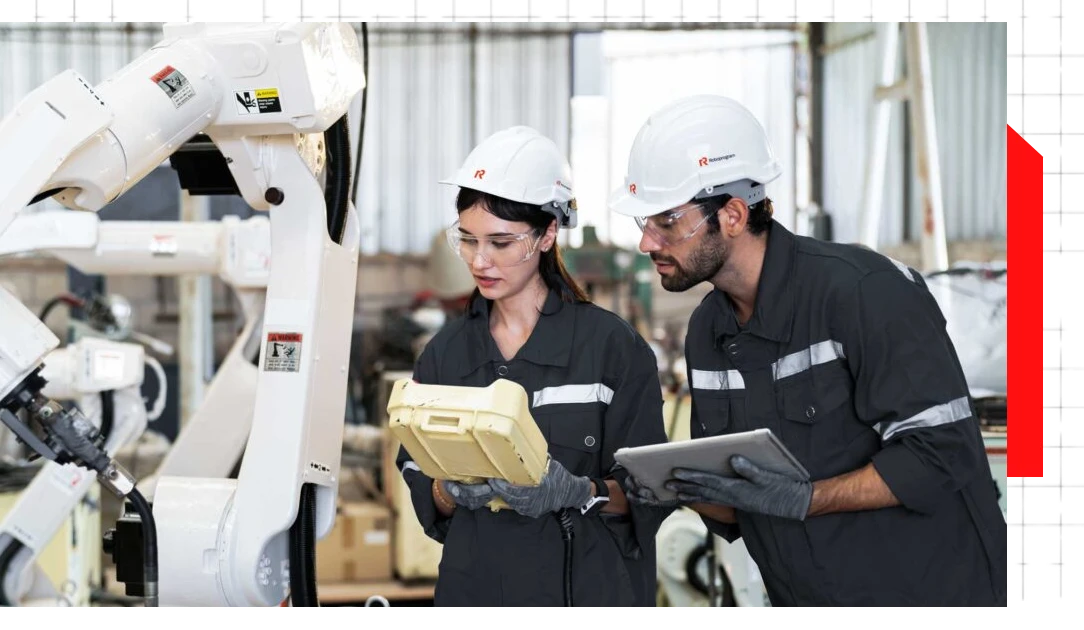

Robot lifecycle management, from design to retrofit, including development, training, and evolutionary assistance to accelerate time-to-market and maintain continuous production, aligned with Industry 5.0.

SMART DEVELOPMENT WORKFLOWS

Our approach to robot programming follows modern IT development practices to:

create variants for individual cells with a clear history

securely manage releases and rollbacks

validate robot behavior in shared digital environments

provide customers with documented deployment packages

maintain a single source of truth for the entire project

PARTNERING WITH MANUFACTURERS

We work closely with the customer and their technical team to define the cell architecture, select end‑of‑arm tools, establish programming standards, and simulate the layout before production. Our experts manage the project both on‑site and remotely, also providing training sessions on robot programming languages (RAPID, TP, KRL) to transfer industry best practices to OEMs.

NOT JUST ROBOT PROGRAMMING

Covering all areas of industrial automation, from software development to system and robot design.

2D/3D CAD modeling for components, industrial plant layouts, and custom machinery.

AI, Digital Twin, Edge‑Cloud Computing, and Cybersecurity to deliver Industry 4.0 solutions.

Development of custom SCADA solutions for accurate monitoring of industrial processes.

Smart PLC program development, testing, and commissioning for reliable system control.

End‑to‑end electrical panels, on‑machine wiring, and technical documentation.