Covering all areas of industrial automation, from software development to system and robot design.

STANDARDIZED, SCALABLE SOFTWARE

We design PLC software to make it modular, extensible, and reusable across multiple models. This unified standard is applied to the entire machine range through shared libraries, project templates, consistent naming, and standardized alarm management.

Our approach allows OEMs to export the same machine to different markets without redesigning the software from scratch.

HIGH-SPEED PERFORMANCE

We apply multi‑axis motion to packaging, assembly, pick‑and‑place, and CNC machines. This enables advanced functions such as electronic cams, flying shear, electronic synchronization, trajectory control, velocity profiles, and tension and web control.

Focus is on motion quality, enhancing servo performance through faster cycles, jerk‑limited profiles, and reduced vibrations.

ADVANCED PLC & AUTOMATION

Creation of reusable PLC libraries integrated into a unified software platform, supported by our guidelines to standardize the work of programmers.

Software testing through a Digital Twin and remote debugging to verify logic, sequences, and cycles with minimal time and resource investment.

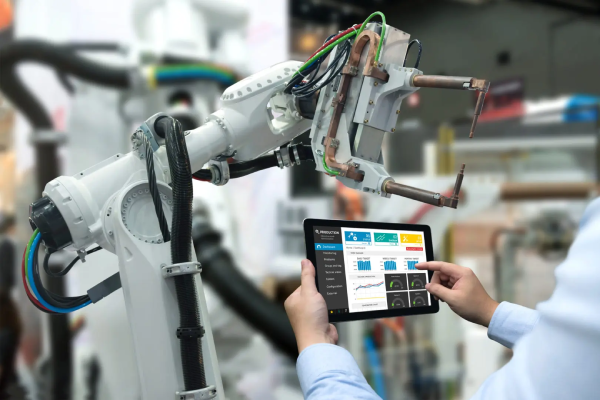

Integration of PLCs, robots, and motion systems, with modern HMIs, MES/SCADA/Cloud interfaces, and data collection to support OEE.

Certified control‑function development on safety PLCs and safe motion, with robust diagnostics, processes based on IEC 61131‑3, code reviews, and test routines.

Customers are supported throughout the entire software lifecycle (requirements analysis, FAT, SAT, training) and even after implementation through revamping, migration, and evolutionary support.

SMART DEVELOPMENT WORKFLOW

Our PLC software management ensures:

fully tracked changes

dedicated branches for each machine variant

controlled and safely reversible releases

Where possible, code is tested in automated environments. In every project, the workflow is shared to make all changes transparent and to best coordinate the entire lifecycle.

PARTNERING WITH MANUFACTURERS

We work with you during the design phase, jointly defining the control architecture, standards, and hardware and software platforms. Our experts can also support internal teams, either on‑site or remotely, providing training and guidance in project management.

NOT JUST PLC PROGRAMMING

Covering all areas of industrial automation, from software development to system and robot design.

2D/3D CAD modeling for components, industrial plant layouts, and custom machinery.

AI, Digital Twin, Edge‑Cloud Computing, and Cybersecurity to deliver Industry 4.0 solutions.

Development of custom SCADA solutions for accurate monitoring of industrial processes.

From needs assessment to commissioning, with smooth integration into production lines.

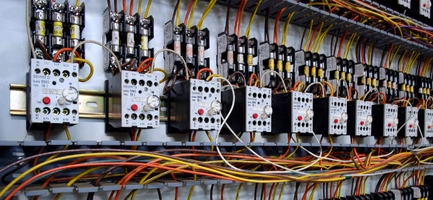

End‑to‑end electrical panels, on‑machine wiring, and technical documentation.